Olie condition monitoring

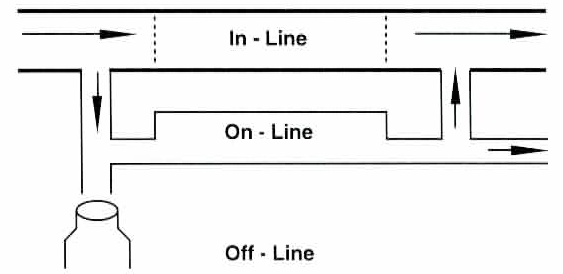

Via OilSense oil sensors it is possible to monitor your oil quality in real time. In-line and on-line sensors can be integrated in your system for continuous oil monitoring.

Alinea

Real-time monitoring has a lot of advantages:

- less laboratory (expensive) oil analysis

- no delay between oil sampling – oil analysis – analysis report

- continuous oil monitoring instead of regular scheduled oil analysis. Immediate action is possible in case of an incipient oil/machine problem

- no small 100 ml samples but a continuous representative measuring result

Alinea

Alinea

Alinea

Alinea

Alinea

Detection of particles in your oil

ISO 4406:1999, NAS 1638 and SAE AS 4059

Alinea

OilSense is specialized in electronic detection of contamination particles in oil. Tailored adjustments are possible. Particle distribution can be displayed as ISO 4406:1999, NAS 1638 en SAE AS 4059.

Alinea

Alinea

Alinea

Alinea

Alinea

Alinea

Alinea

Moisture detection in your oil

% watersaturation, ppm

Alinea

For your specific application OilSense selects the best price/quality moisture (water/humidity) oil sensor. The chemical phase of water in oil is strongly temperature dependent. Therefore OilSense recommends water in oil measurements @ your machine through an integrated sensor.

Alinea

Alinea

Alinea

Alinea

Alinea

Alinea

Measurement of the remaining useful life of your oil

% remaining useful life

Alinea

These oil analysis measurements help determine if the extended useful life of a machine lubricant is possible before oil drainage, saving cost and avoiding the risk of oil failure and equipment damage.

Testing for antioxidant levels in machine lubrication oils will provide an assessment of the condition and ability of the oils to resist oxidation, a major contributor to lubrication failure. Routine testing measures the depletion rate of antioxidant additives present in the oil, allowing for a prediction of the remaining useful life of the lubricant.

Alinea

Alinea

Alinea

Alinea

Measurement of oil viscosity, relative dielectricity, water, temperature and particles

Alinea

The most important physical oil parameter is the viscosity. Sudden changes in viscosity or relative dielectricity indicates a (starting) oil problem. An oil viscosity change may cause catastrophic damage to your machine. A continuous viscosity measurement is recommended by OilSense.

Alinea

Alinea

Alinea

Alinea

Mobile oil analysis lab

OilSense offers a range of sensors for analysis of:

- oil chemistry (detection of a wrong oil supply)

- oil oxidation

- oil nitration

- oil sulfation

- presence of water

- presence of glycerin

- concentration of antioxidants

- concentration ant-wear additives

Alinea

Our sensors can be used for in-line, on-line or off-line oil condition monitoring.

maintenance 24/24 service intervention repairing overhaul repair rental sales renting buy Hydraulic hydraulics lubrication lubricating Oil sampling bottle apparatus laboratory oil sample vacuum pump oil monster interpretation interpreting oil analysis oil analysing MPC membrane patch colorimetry TAN AN FTIR IR NAS 1638 ISO 4406 : 1999 SAE AS 4059 analytical ferrography viscosity PQ Particle quantification index lineair sweep voltametrie LSV RULER XRF spectrometry Karl Fisher improve breakdown voltage filtration 0,8 µm Gassing Inhibitor (DBPC) surface tension (IFT) dissolved gasses metals oxidation stability PCB RPVOT Sediment en Sludge IEC Stray gassing cleanliness level COC flash point FT-IR Oxidation Conradson Carbon Residue foam test DGA dissolved gas analysis tribology varnishes tars gums lacquers deposits pigments resins

neutralisatiegetal Aniline punt Dielectrische dissipatiefactor Furaanderivaten Poly Aromatische Koolwaterstoffen (PAK) Passivator (Irgamet 30 – TAA) Passivator (Irgamet 39 – TTAA) Passivator (TTA en BTA) Resistiviteit Vlampunt (Cleveland OC) setaflash Vlampunt (Pensky Martens CC) Vloeipunt onoplosbaar @ 0.45 µm (n-heptaan) schuimkarakteristieken, sequence I waterafscheidend vermogen luchtafscheidend vermogen kopercorrosieweerstand staalcorrosieweerstand oil filtration oil filter skid hydraulic oil removal of moisture humidity water in oil contamination particle water contamination purifiers vacuum dehydration dehydrator oil dryer oil drying degassing oil separator flush unit flushing mobile offline filtration kidney loop by-pass bypass separate filtration oil filter change air breather depth filtration pressure inline filters dewatering unit β bèta ratio filter housing filter efficiency ESD electronic spark discharge filter element oil foaming oil foam online inline offline sensor oil sensor watersaturation ercentage saturation particle moisture humidity sensor particle counting in oil water sensor in oil dielectricity oil managment asset management lubrication oil mineral synthetic oil motor engine oil transmission oil compressor oil turbine oil insulating oil transformer oil foodgrade oil bio oils condensation reservoir tank oil cooler cooling heater heat oil heat exchanger steam gas turbine phosphate esters fuel clean oil

hydraulic press transformer mobile hydraulics plastic injection moulding plastic moulding Bosh Rexroth Eaton Internormen Pall CC CJC Jensen Hydac Parker Hannifin Kittiwake Triple R 3R Argo Hytos Eppensteiner Epe MP Filtri Cardev RMF Hypro Hy-pro MAHLE Vaisala Kleenoil Cleanoil OilSafe Olaer Oiltech Testo Fluke Hydrotechnik Mann FluidDefense Oil Safe Label safe Grease Safe Lubristation Decolube Elcolube Air Sentry Lube IT Mobilube SF Filter Fluitec Stauff Mobil Shell Hiac Royco Afghanistan Albania Algeria American Samoa Andorra Angola Anguilla Antigua & Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas, The Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bermuda Bhutan Bolivia Bosnia & Herzegovina Botswana Brazil British Virgin Is.

Brunei Bulgaria Burkina Faso Burma Burundi Cambodia Cameroon Canada Cape Verde Cayman Islands Central African Rep. Chad Chile China Colombia Comoros Congo, Dem. Rep. Congo, Repub. of the Cook Islands Costa Rica Cote d’Ivoire Croatia Cuba Cyprus Czech Republic Denmark Djibouti Dominica Dominican Republic East Timor Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia

Ethiopia Faroe Islands Fiji Finland France French Guiana French Polynesia Gabon Gambia, The Gaza Strip Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guam Guatemala

Guernsey Guinea Guinea-Bissau Guyana Haiti Honduras Hong Kong Hungary Iceland India Indonesia

Iran Iraq Ireland Isle of Man Israel Italy Jamaica Japan Jersey Jordan Kazakhstan Kenya Kiribati Korea, North Korea, South Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Macau Macedonia Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Martinique Mauritania Mauritius Mayotte Mexico Micronesia, Fed. St. Moldova

Monaco Mongolia Montserrat Morocco Mozambique Namibia Nauru Nepal Netherlands Netherlands Antilles New Caledonia New Zealand Nicaragua Niger Nigeria N. Mariana Islands Norway Oman Pakistan Palau Panama Papua New Guinea Paraguay Peru Philippines Poland Portugal Puerto Rico

Qatar Reunion Romania Russia Rwanda Saint Helena Saint Kitts & Nevis Saint Lucia St Pierre & Miquelon Saint Vincent and the Grenadines Samoa San Marino Sao Tome & Principe Saudi Arabia

Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa Spain Sri Lanka Sudan Suriname Swaziland Sweden Switzerland Syria Taiwan Tajikistan Tanzania Thailand Togo Tonga Trinidad & Tobago Tunisia Turkey Turkmenistan Turks & Caicos Is

Tuvalu Uganda Ukraine United Arab Emirates United Kingdom United States Uruguay Uzbekistan

Vanuatu Venezuela Vietnam Virgin Islands Wallis and Futuna West Bank Western Sahara Yemen

Zambia Zimbabwe